To spread lean knowledge and escort the development of enterprises, Jingji Technology's low-cost automation special training camp started

Release Time:

2023-06-06

Summary: Design your own low-cost automation equipment.

Low-cost automation is referred to as LCIA

It is a solution that replaces inefficient work with simple automation at low cost.

Do you have a lot of doubts about LCIA?

How to apply LCIA to work scenarios?

How to reduce production costs really and effectively?

Are you also looking for experts in this area?

Low-cost automation escorts lean production for enterprises

At present, "waste, imbalance and unreasonableness" have become the three major problems restricting manufacturing costs. To this end, people are trying to actively respond, and automation has become the choice of more enterprises. But from the user's point of view, employees do not care whether the equipment is automated, as long as it is useful, if it is simply to pursue automation, it will often lead to putting the cart before the horse.

"Do not seek the most expensive, but seek the best", clever improvement is to take practicality as the starting point, the original intention of low-cost automation design should start from "how to use the minimum cost to achieve the requirements of employees", through the use of lean and clever equipment, to achieve "small batch, multi-variety" flexible production, with low investment lean concept and simple and practical tools, so as to improve efficiency and product quality, to achieve cost reduction.

Intelligent automation, low-cost ingenuity improvement

"Do you know gravity, elasticity, levers?"

"I understand all this, but how can I use it to better effect?"

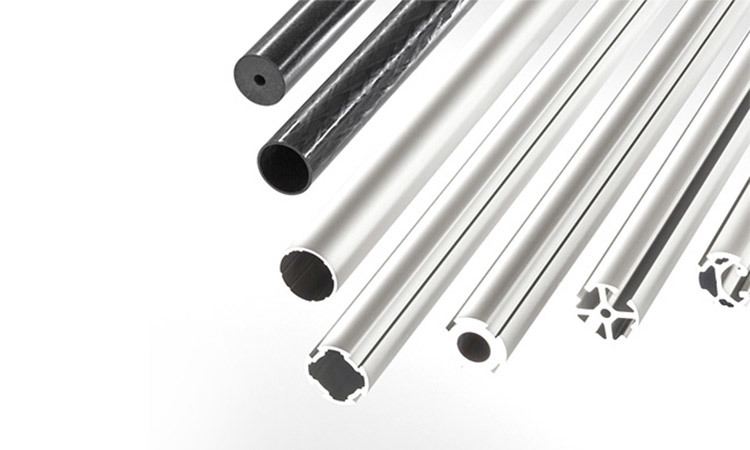

In fact, seemingly complex clever improvement devices are not so difficult to achieve, and simple mechanical principles are commonly used. In order to enable front-line employees, engineers, front-line team leaders, etc. to quickly master the skills of device design and assembly, and improve the low-cost automated production level of LCIA, Jingji Technology is committed to enriching more enterprises' cognition and application practice skills of lean pipe fittings through the application and practice courses of three generations of aluminum alloy lean pipe fittings and lean pipe fittings application and practice courses, shortening the assembly time of the device, and scientifically and reasonably applying lean pipe fittings, so as to better realize the manufacturing upgrading of enterprises. Reduce costs, reduce investment risks, and increase employee productivity and motivation.

This three-generation aluminum alloy lean pipe fittings application and practice course includes the basic knowledge of lean pipe fittings, the introduction of three generations of lean pipe fittings products and lean pipe fittings device design and production skills, which lasts for 1 day. The Lean Fittings Application and Practice Course includes the basic knowledge of lean fittings, the introduction of lean fittings products, the design and production skills of lean fittings and excellent enterprise cases, etc., which lasts for 2 days. Both courses are suitable for IE Engineering Department, Equipment Department, Automation Department, Workbench Production or Device Design and Production Related Personnel.

Three generations of aluminum alloy lean pipe fittings application and practice course arrangement (1 day).

Lean Fittings Application and Practice Course (2 days).

Schedule for the first day

Classes are scheduled for the second day

"Teaching people to fish is not as good as teaching people to fish", direct purchase of automated equipment can undoubtedly improve production efficiency, but the user's lack of understanding of the principle and adjustment method will make the equipment just a simple tool, but once the work content is changed, it is difficult to be useful. Therefore, it is important to improve the formation of thinking, master the application principle of lean pipe fittings, practice makes perfect, which is also the core of this training.

Lean has no end, transformation has no end. There is no shortage of areas for improvement in the work, and as long as knowledge and practice are used wisely, the role of clever improvement can be fully utilized.

Prev:

Related News

2023-06-06

To spread lean knowledge and escort the development of enterprises, Jingji Technology's low-cost automation special training camp started

Summary: Design your own low-cost automation equipment.

2023-06-06

Introduction to the application and advantages of low-cost automation in enterprises

Low-cost automation refers to the use of simple, easy-to-implement and low-cost technical means to automate some links or entire processes in the traditional manual operation process. It is different from high-cost automation, which can reduce costs and improve production efficiency while realizing automation.

2023-06-06

Introduction to Low-Cost Automation in Production

Low-cost automationIt refers to automating production processes while reducing costs through the use of simple, easy-to-implement technologies and equipment.

2023-06-06

What is a wire rod turnover car?

The wire bar turnover cart is a special vehicle used to transport wire rods, which is commonly used in the production process in the textile, printing and dyeing, paper and other industries. The main function of the wire bar turnover trolley is to transport the wire bar from one production link to another to ensure the smooth progress of the production process.

Online Consultation